AAC Manufacturers

AAC plant unit is proposed to manufacture AAC Blocks by consuming the Fly-Ash as one of the prime raw material. Fly-Ash, a major raw material with 70% proportion in AAC Blocks is a waste by-product of Thermal Power Plants, is an environmental threat across the globe. Power plants are facing an ever increasing challenge disposal of this polluting Fly Ash.

Main ingredients include fly ash, water, quicklime, cement, aluminium powder and gypsum. The AAC block strength is being achieved by binders like lime and cement curing mechanism by autoclaving. The chemical reaction due to the aluminium paste provides AAC different when compared to other lightweight concrete materials.

The finished AAC block is a 2.5 times lighter Block compared to conventional Bricks, while providing the similar strengths. The density is around 0.5 to 0.65. This is one single most USP of the AAC blocks, because by using these blocks in structural buildings, the builder saves around 30 to 35 % of structural steel, and concrete, as these blocks reduce the dead load on the building significantly.

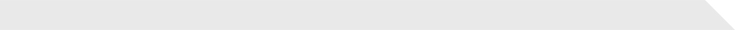

Buildmate’s highly technically competent manufacturing capabilities are a result of its tradition of anticipating and fulfilling specific Autoclaved Aerated Concrete plants customer requirements. A qualified team of engineers and technicians, supported by the modern IT infrastructure enable us to meet the needs of our AAC plant customers on time.

Latest Gallery

Exhibition

Bauma Munich 2016

Munich, Germany.

Our management team consists of young, yet seasoned professionals with vast experience, a passion to succeed and a strong vision for the company.

Read MoreFAQ's

Can we use AAC Blocks for load bearing structures?

You can use AAC Blocks for load bearing structures upto 3 storeys.

What are the ingredients?

Cement, Gypsum, Lime, Silica Sand, Aluminum Powder and Water.

Read More

AAC Plant Manufacturers